The Evolution of Roller Coaster Design

August 16th is national roller coaster day in the United States, which means that in a couple of days, thousands of people all across the country will either be putting their hands up, getting queasy, getting scared out of their minds, or laughing on a roller coaster. Even if you’re not a huge roller coaster fan like I am, it’s hard to not at least appreciate the hard work and technical expertise that go into designing them. Additionally, their design has improved significantly over the years. Countless technological innovations in recent history have made new roller coasters safer, more comfortable, more reliable, and more extreme than ever before. Let’s take a look at a couple of the ways roller coaster design has evolved over time so you can see how broad design principles can influence even the most niche areas of engineering. As a bonus, you’ll be able to show your friends how much of a design nerd you are the next time you’re all in line for a roller coaster.

Design Innovation 1: Loop Shape

Figure 1: The Revolution at Six Flags Magic Mountain, photo taken by Rick Turner

Pictured above is the vertical loop featured on The Revolution at Six Flags Magic Mountain, which was the first roller coaster to ever open with a vertical loop when it opened in 1976. As you can see, the loop is almost a perfect circle. In order to reduce the stress in the track and on the riders, vertical loops nowadays are more of an inverted-teardrop shape as pictured below:

Figure 2: Dominator at Kings Dominion, photo taken by Duane Marden

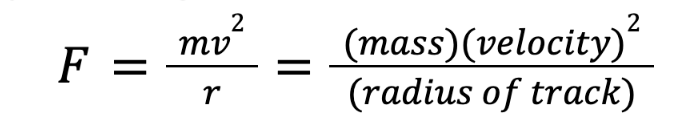

The reason why an inverted teardrop shape reduces stress in the track lies behind a fundamental physics principle. Here is the equation for centripetal force, or the force exerted on a circular track by an object traveling on it:

This means that if the radius of a loop is smaller, then the train will exert a larger force on the track. Inverted tear-drop shaped loops give the bottom part of the loop, the part where the train is going fastest, a larger radius so the force is reduced. The train then goes through the top part of the loop (with a tighter radius) at a reduced speed, which is much better on the track. This basic physics principle made vertical loops less strenuous on the track and more comfortable for riders due to the decreased forces.

Design Innovation 2: Improved Wooden Roller Coaster Track

I love wooden roller coasters, but they sometimes get a bad reputation for being rough and uncomfortable. This is because wood deflects (changes shape without breaking) much easier than steel, which makes the ride bumpier as time passes because the track strays from how it was originally installed. Yearly maintenance and retracking is required to make sure that wooden roller coasters can continue to run safely and comfortably. A few years ago, The Gravity Group set out to solve the wooden roller coaster maintenance problem once and for all by designing new track that would reduce deflection, therefore decreasing maintenance costs. Wooden roller coasters are usually constructed by carpenters who cut and assemble the track on site, which consists of multiple wooden boards stacked on top of each other. However, the Gravity Group’s new precut track — which is assembled in a factory and then shipped to a park for installation — consists of boards positioned vertically lined up side by side, as shown below:

Figure 3: The Gravity Group’s precut track on the left

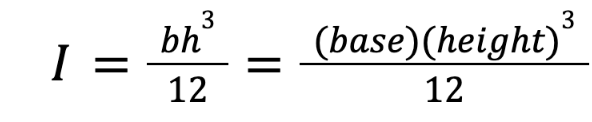

The picture shows that the vertical configuration deflects much less than the horizontal (traditional) configuration. This new configuration greatly increases the moment of inertia (another fundamental physics principle) of the track and makes it deflect much less than traditional wooden roller coaster track. The moment of inertia of a rectangle is:

This means that a rectangle is harder to deflect if its mass is distributed more vertically as opposed to horizontally. This basic physics principle revolutionized wooden roller coaster design and reduced maintenance costs and improved the rider experience worldwide [1].

Design Innovation 3: The Modern Block Zone

In the early 20th century, roller coasters had brake operators on them that rode with the riders and operated manual brakes, much like a normal car. There were no brakes on the physical track, just on the train. This made it so the ride could not be terribly extreme since the brake operator would need full control of the brakes at all times, and if he failed to do his job, then two trains would crash into each other if multiple trains were being used on the ride at the same time.

Figure 4: Rutschebanen at Tivoli Gardens, photo taken by Rik Engelen

This problem inspired the idea of block zones. A block zone is a section of track that can only have one train on it at a time. Every block zone is separated by a brake built into the track, which is usually a magnet that interacts with metal on the train and slows it down. This eliminates the need for a brake operator on the train since the different block zones can communicate autonomously with each other and only permit one train at a time to traverse a certain section of track [2]. This is also why mid-course brakes in the middle of the ride are usually elevated high off the ground. If an emergency happened and the train needed to come to a complete stop in order to not collide with another train, the train would still have sufficient speed to traverse the rest of the track without assistance when it is deemed safe since the train would build up enough speed from the mid-course brake’s elevated height. Modern block zones that utilize sophisticated computer programs have increased safety and made it so your life doesn’t depend on one brake operator.

Conclusion

Figure 5: Skyrush at Hersheypark, my personal favorite roller coaster

As you can see, new design innovations have made roller coasters more dynamic, safer, more reliable, and more fun! Even an industry as niche as roller coaster engineering has benefitted from broad design principles and using physics fundamentals in unprecedented ways. I’m grateful for roller coasters because they got me interested in engineering in the first place. Growing up, I was so captivated by the fact that so much science was necessary to create so much fun. Engineering is often described as, “The application of science and math to solve problems” [3], and not many branches of engineering focus entirely on the problem of “how can we have the most fun possible?” So on National Roller Coaster Day, let’s celebrate roller coasters, one of the most complex subsets of engineering that entirely concerns itself with fun. Even engineers need to have fun every once in a while.

REFERENCES

[1] The Gravity Group. "Engineered Precut Track." The Gravity Group, https://thegravitygroup.com/home/engineered-precut-track/.

[2] "Coasters 101: Brakes, Blocks, and Sensors." Coaster101, 23 Nov. 2011, https://www.coaster101.com/2011/11/23/coasters-101-brakes-blocks-and-sensors/.

[3] "What Is Engineering?" University of Bath, https://www.bath.ac.uk/campaigns/what-is-engineering/#:~:text=Engineering%20is%20the%20designing%2C%20testing,lead%20to%20a%20rewarding%20career.

To cite this article:

Ipsen, Blake. “The Evolution of Roller Coaster Design.” The BYU Design Review, 11 August 2025, https://www.designreview.byu.edu/collections/the-evolution-of-roller-coaster-design.