Mechanical Design

“As someone who loves design of all kinds, it can be easy to get carried away and lose track of where I, as a mechanical engineer, fit in the design world. For me it is important to understand what makes mechanical design different than any other kind of design. Understanding this puts me in a better position to know how my specific training and design decisions can affect the world. ”

The context for mechanical design

The built environment refers to the human-made environment that provides the setting for human activity [1]. This includes: cities, parks, buildings, work places, transport infrastructure, and other similar environments. The design of the built environment is generally the purview of civil engineers, architects, city and urban planners, and public health designers.

Within the built environment are countless designed objects that relate to or facilitate human activity. These include cars, tools, computers, furniture, appliances, processed food, clothing, books, art, and more. The design of these objects is generally the work of industrial designers, mechanical and electrical engineers, furniture designers, chefs and food scientists, artists, authors, and others.

The built environment, together with designed objects, represent the bulk of what most of us see and interact with each day. Interestingly, the built environment and designed objects have evolved to the point that a new environment is now an equal player in the modern world – that is the virtual environment. This includes all the digital items we access through the screens of our electronic devices. Computer scientists, web designers, and coders of all kinds are the creators of this environment, while the digital items within that environment have come from people everywhere in the form of emails, photos, videos, music, and more.

The built environment, the virtual environment, and designed objects can be highly interconnected. The mobile phone is a clear example of this. As a designed object, its main purpose is to provide access to the virtual environment, and this is only possible when it connects to a cell tower, which is part of the built environment.

The ecosystem created by these three elements – the built environment, the virtual environment, and designed objects – has a profound influence on our quality of life. Therefore, the ability of design professionals to thoughtfully create meaningful, imaginative, stimulating, and effective designs is important to everyone [2].

What is the specific role of mechanical design in the ecosystem?

I find many aspects of the ecosystem interesting and inspiring, even though I have no formal training, nor responsibility for those aspects. For example, I love architecture, but don’t know enough about it to accurately classify the architectural style of most buildings. I appreciate art, but have never taken a class. I have a goal to make a piece of furniture this year, but haven’t done it yet (though I have sketched some furniture and dabbled with printmaking as a creative outlet).

Wingback Chair Sketch (C. Mattson)

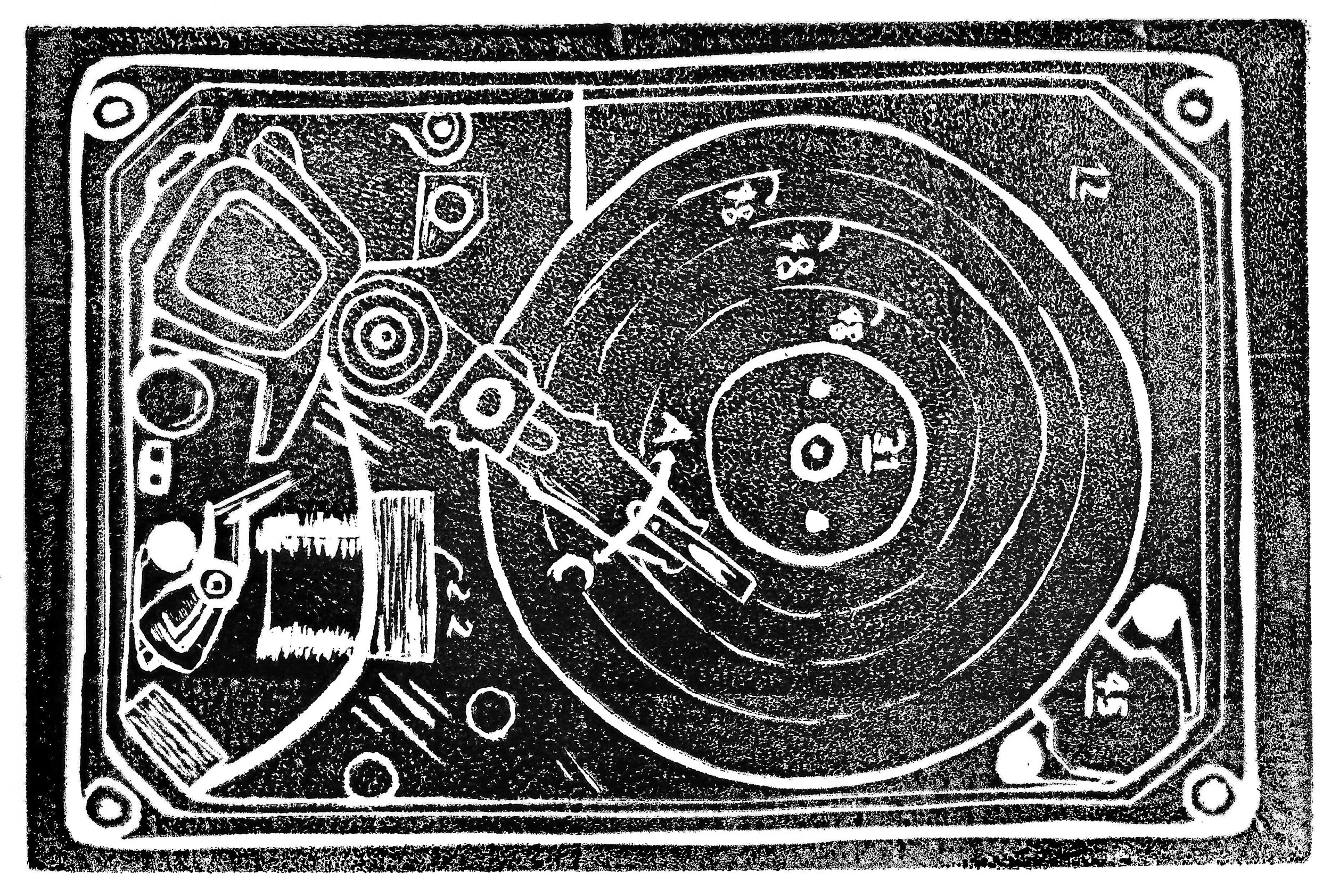

Eames Lounge Chair Print (C. Mattson)

As someone who loves design of all kinds, it can be easy to get carried away and lose track of where I, as a mechanical engineer, fit in the design world. For me it is important to understand what makes mechanical design different than any other kind of design. Understanding this puts me in a better position to know how my design decisions affect the well-being of those who interact with objects I design.

Mechanical designers are well-positioned to design objects within the built environment, but are usually not well-suited to design the built environment itself, nor the virtual environment. Importantly, because designed objects sit within the built environment and are the means through which people access the virtual environment, it is valuable for mechanical designers to recognize that the design of an object is often not enough. One must also design the experience associated with using that object in the built environment or to access the virtual environment.

The design of objects, however, is the concern of various professionals including industrial designers, engineers, and others. What specific role does mechanical design play in the design of objects and how people use them? To answer this question, let’s first consider what mechanical design is, then take a glimpse into the mechanical design process.

What is mechanical design?

Mechanical design is the activity/process needed to conceive and develop a part, product, or system [3] that achieves specific functionality, reliability, and/or usability [4].

Successful mechanical design generally applies scientific and mathematical knowledge to efficiently develop the product (i.e., to avoid random trial and error) [3]. This knowledge often centers on energy processes, movement of solids or fluids, and/or mechanical stress, strain, and strength.

The primary variables of mechanical design are part geometry, material, and manufacturing process needed to create it. Design decisions made within this triad of variables are generally highly interdependent.

Mechanical design concerns itself with the relative position, fit, and movement (or lack of movement) between a product’s parts/features and/or between it and the environment around it.

The process of mechanical design [5]

Mechanical design starts by understanding what functionality, reliability, and usability are required for the part/product to be considered desirable. Good mechanical design is more likely to result when the designer gets outside of himself or herself and engages with stakeholders, examines products that achieve similar functionality, and avoids making unvalidated assumptions about what is required.

With a basic understanding of what is required the mechanical designer enters a concept exploration phase, where many basic ideas are considered. These ideas are generally centered on the arrangement of various structural, electrical, cosmetic, or machine parts, and how they will interact to produce the desired functionality, reliability, and/or usability. This can include parts such as frames, motors, bearings, hinges, fluids, pipes, valves, labels, handles, circuits, switches, and more. An understanding of basic machine elements facilitates the synthesis of product concepts, as does the construction of basic prototypes. A culminating part of the exploration phase is to converge on a concept that has a high chance of meeting the product requirements. Converging is best done when it involves feedback from multiple stakeholders.

The first two phases of the mechanical design process (understand and explore) are highly interconnected. For example, while exploring concepts, more becomes known about the requirements, which are then updated and used to generate additional concepts and/or to refine the choice of which concept to go with.

Once a promising concept is selected, the mechanical designer begins the detailed engineering of the product. This means that the specific and exact geometry of all parts is chosen and defined, as well as the material of each part. This phase in the process is much more than simply writing down what the product’s dimensions are, it’s working out all the details that transform a basic concept into a detailed product that can be manufactured. Working out those details is facilitated by the designer’s understanding of energy processes, movement of solids or fluids, mechanical stress, strain, and strength, and other physical phenomena. Calculations are often carried out in the mechanical design process to predict the behavior of the product and to experiment with various parameter values in preparation for the physical testing.

During the last phase of the mechanical design process, the detailed product is built and tested. Testing involves both a verification that the product requirements are met, and a validation that the stakeholders are satisfied.

Like the first two phases of the mechanical design process (understand and explore), the last two phases (defining the product details and testing them) are also highly interconnected. As such, the mechanical designer will expect to create a detailed product, test it, find deficiencies that lead to a refined detailed product, which is then tested again, repeating until the stakeholders are satisfied.

Who does mechanical design?

Various people, of various skill levels and education do mechanical design. Mechanical engineers who are responsible for conceiving and developing engineered parts, products, or systems do mechanical design, and are particularly well-suited for it. In truth, anyone engaged in all four of the bullets listed above is doing mechanical design (see What is mechanical design?). As with all skills, some people are better at it than others. What makes one better at it often has to do with training, practice, and experience. But there can also be some natural skill and inclination that have driven some people to become exceptionally talented.

So what?

Nearly everything around us is designed, therefore design significantly influences human activity and quality of life. Various design professionals from a wide range of disciplines contribute to this reality. Mechanical designers play an important role in that they design objects that are meant to achieve a specific functionality. This functionality is improved as a part’s geometry, material, and manufacturing process are thoughtfully changed by mechanical designers in pursuit of desirable product performance. This performance is often related to energy, movement, and/or mechanical strength. Considering the mechanical designer’s role in the design world, I am particularly encouraged by something architect and industrial designer Jack Howe expressed, when he said “…An engineering designer is just as creative as any other sort of designer.”[2]

Cover art “Hard drive” by A. Mattson (2020)

References

[1] Wikipedia, “Built Environment,” https://en.wikipedia.org/wiki/Built_environment, Accessed 10 July 2020.

[2] N. Cross, Design Thinking; Understanding how Designers Think and Work, 2011, Bloomsbury Academic.

[3] P. Childs, Mechanical Design Engineering Handbook, 2014, Elsevier.

[4] W. Lidwell, K. Holden, and J. Butler, “Hierarchy of Needs,” Universal Principles of Design, 2003, Rockport.

[5] C. Mattson and C. Sorensen, Product Development: Principles and Tools for Creating Desirable and Transferable Designs, 2020, Springer Nature Switzerland, Cham.

To cite this article:

Mattson, Chris. “Mechanical Design.” The BYU Design Review, 10 Jul. 2020, https://www.designreview.byu.edu/collections/mechanical-design.