Computer-Aided Design

“When I was an engineering student I took three CAD classes, mostly because they were fun. When I was the director of engineering at ATL, CAD was at the center of all our detailed design work. It was indispensable to our engineering. When I became a professor, however, my appreciation for CAD slowly and unconsciously faded. Luckily, a new university assignment has put CAD back on my radar and my appreciation for it is greater than ever.”

What is Computer-Aided Design (CAD)?

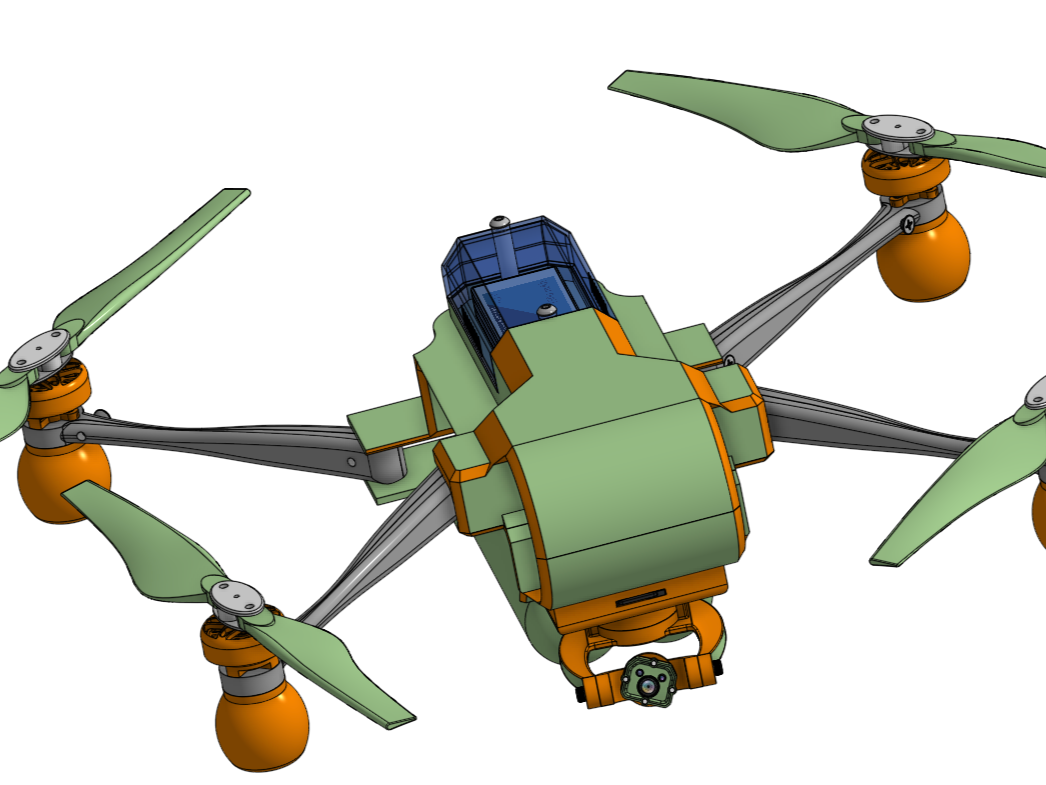

Although the acronym “CAD” has a somewhat messy history [1], it is now known to mean computer-aided design and refers to the use of computer technology to design things such as objects and structures. CAD is used in mechanical design, industrial design, architecture, animation, advertising, and other industries [2]. Within mechanical design [3], CAD is used to facilitate the creation, analysis, modification, and optimization of physical objects.

CAD Model of Braun ET66 Calculator. Model by C. Mattson.

While CAD was originally developed to partially automate the time-intensive manual drafting process [1], its greatest benefit now lies in facilitating design iteration and enabling distributed design collaboration. CAD’s semi-automated way of creating technical drawings is still a major plus.

Although the words computer-aided design, could be so broadly interpreted as to mean using any computer technology such as email, word processors, and spreadsheets, CAD refers specifically to the use of commercial software for creating accurate geometric digital representations of three-dimensional objects such as gears, shafts, enclosures, etc.

The Primary and Secondary Outputs of CAD

The Solid CAD Model, is the primary output of CAD. This primary output, which is a computer file (or set of files), is indispensable for visualizing and evolving a design. Further, the solid CAD model is almost always used to produce essential secondary outputs including technical drawings, bill of material, renderings, finite element analyses, animations, and more. It is important to recognize that the solid CAD model is “the source of the design database and is the authority from which all other CAD outputs flow” [4]. In the design of engineered objects, solid CAD models serve as “the central point of the development process and the main data source used and shared by most stakeholders” [5].

Primary CAD Output: Solid CAD Model.

Secondary CAD Output: Technical Drawing

Secondary CAD Output: Mesh and Finite Element Analysis

The digital representation of the part in the solid CAD model is constructed with one or more solid CAD operations/features such as extrudes, revolves, sweeps, cuts, fillets, and chamfers. Each operation is captured in an ordered list called a feature manager, or design tree. These trees are powerful because when the CAD model is well-constructed, features can be easily turned off and on in the design tree or rearranged as needed. In essence, all CAD programs construct a part in this way with these same basic operations/features, which means that once you have learned one CAD program, it is relatively easy to learn another.

CAD Model Quality

Because the solid CAD model is the primary output of CAD, it is valuable to understand what constitutes a good solid CAD model. Good solid CAD models are:

Geometrically and materially accurate. Specifically:

They are constructed to appropriate one-to-one scale and units

They include appropriate unambiguous geometric features

They assign appropriate unambiguous material to parts

Reusable/Changeable/Robust. This means:

They are generally comprised of operations that are fully defined

The parent/child relationships are meaningful and minimal

They make meaningful use of symmetry and other relationships

Constructed based on sensible design intent. This means, for example:

Unwanted holes are deleted, not filled

Fillets are made with fillet command, not sweep-cuts

Holes meant to go through everything are made thru all, not blind

An extruded part length is changed by updating the extrude feature, not adding a cut to remove unwanted material

Useful for efficiently producing secondary outputs. For mechanical parts this generally means:

Resulting parts are solids, not surfaces

Parts in the assembly are realistically constrained; parts that are supposed to move are left unconstrained in the appropriate degree of freedom

Parts in the assembly have realistic gaps and interferences

Useful for collaboration. This often means making it easy for someone else to understand and use the model. This can often require:

Parts and assemblies to be meaningfully named

Part features to be renamed, and comments added to facilitate design tree navigation

Assemblies to be shared without reference to local computer file structures. Without this, assemblies are not easily opened by collaborators.

Parametric Modeling Makes CAD Powerful

What makes engineering CAD models so powerful is that they are constructed parametrically. This means that everything in the design tree is defined with changeable parameters, which facilitates design iteration. For a simple cylinder, the shape is defined by the diameter and the length. Parametric modeling allows the value of diameter and/or the value of length to be changed anytime resulting in an updated representation of the cylinder. Without parametric modeling, the cost of design changes would be high, causing many to avoid changing the cylinder size, for example, even if doing so would improve the design. Importantly, the parameters of a model can be accessed from outside of the CAD system, which allows rapid CAD model construction using APIs or design tables driven by design spreadsheets.

An Essential Key to Success: The CAD Strategy

Although parametric modeling is powerful, it is not at all foolproof. A significant responsibility still rests on the designer to construct models that are robust and reusable. Regarding this responsibility Camba, Contero, Company said [5]:

“It is essential to select a well-thought-out modeling methodology to ensure an efficient functional model and minimize the time and effort involved in performing modifications based on the characteristics and requirements of the part. The process, however, is not easy. Selecting a specific strategy and making modeling decisions are activities that strongly depend on the users cognitive abilities and her experience and skill to understand and break down the design.”

A CAD strategy is the plan of action a designer will follow when creating the solid CAD model. It is generally written and/or sketched on a piece of paper. Only after a preliminary CAD strategy is in hand, should the digital work begin.

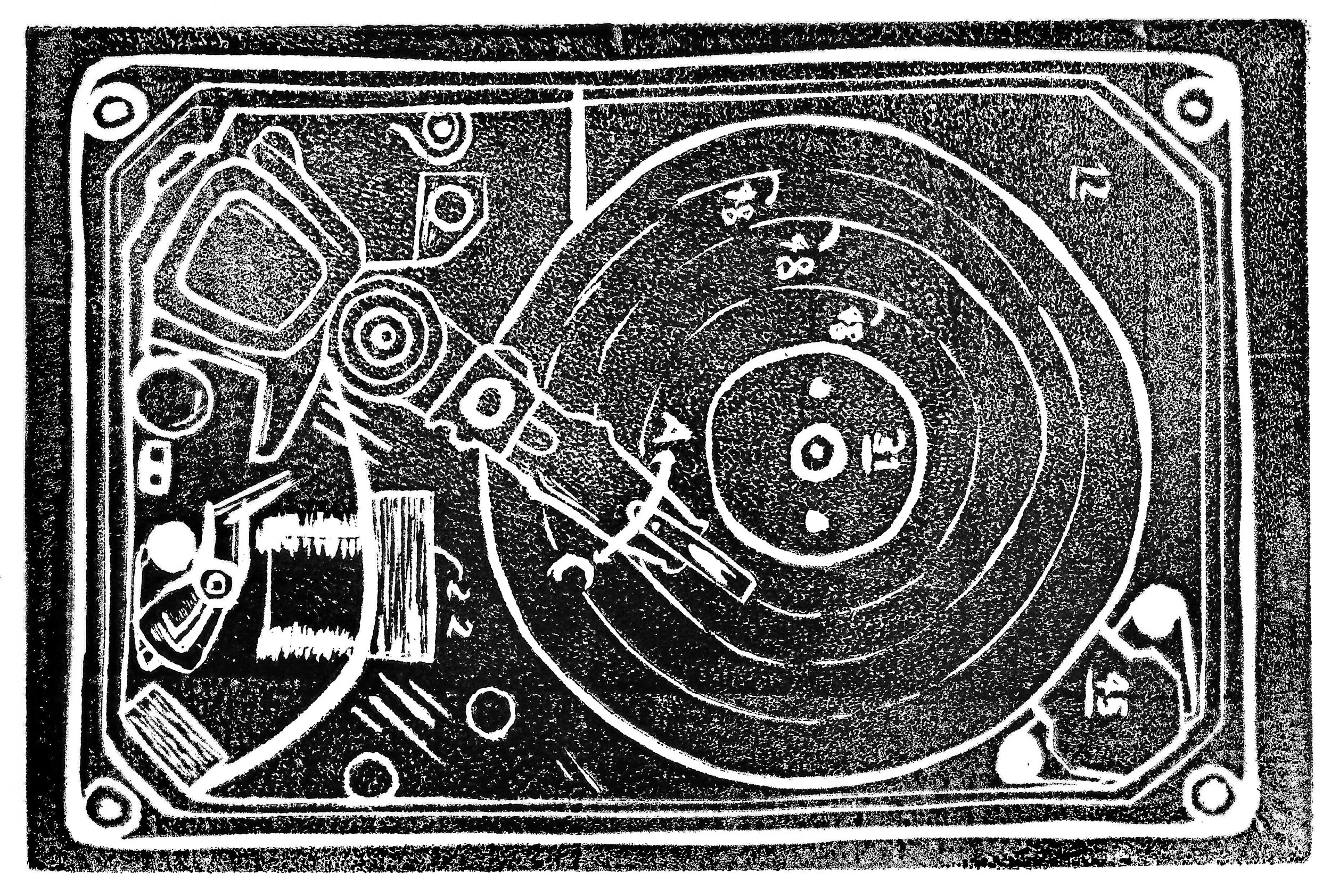

CAD Strategy for Braun ET66 Calculator, by C. Mattson

The CAD Strategy is based on breaking down, or decomposing, the part into CAD features (extrudes, cuts, revolves, sweeps, lots, fillets, chamfers, etc) that can be completed to construct the part. The order of operations when constructing CAD models can be very important as it can change the outcome, therefore CAD strategies articulate sequential construction steps. The dependency of CAD features is also very important, as it influences how reusable a model will be; therefore CAD strategies reference key datums and other features that will be used to construct each critical feature, since these will determine dependencies.

Generally, the CAD strategy is driven by these important decisions:

What features will I create by adding material?

What features will I create by subtracting material?

Are there any patterns?

Is there any symmetry?

What might I want to change later?

For realistic parts, there are multiple good strategies that can be taken, and multiple bad strategies. Spending a few minutes to develop a CAD strategy before beginning the digital work, will ultimately save you noticeable time. I always spend less than 10 minutes writing/sketching out my CAD strategy. Like all design activities, your CAD strategy will evolve as you build the part, or while you’re thinking through your strategy. For example, I added “2 (insert)” in the bottom-left of the strategy above after all other steps were written, since I had forgotten it, and leaving it out would produce a different result. Allow the strategy to evolve when and if your original strategy fails to produce the outcomes you need.

My CAD Process

I approach CAD with 5 deliberate and conscious steps, which I remember as US-MAP. When I find myself in trouble with my CAD model, it is generally because I was not careful about one of these steps.

U – Understand the purpose of the solid CAD model: It could be a requirements model (meaning it will define the precise geometry for a supplier), shape model (which concerns itself with only the outside shape, perhaps for use in a wind tunnel), physics model (this is often a simplified model that will be used for Finite Element Analysis), cosmetic model (focused on appearance and often key attachment points for interaction with other parts).

S – Sketch (hand sketch) the basic part/assembly that will be modeled and the CAD strategy you’ll use to create it.

M – Model. Create the solid CAD model.

A – Analyze the model for design and model quality. For design quality make sure the features are realistic, can be manufactured, and meet the design requirements. For model quality make sure it accurately reflects your decisions and design intent and is reusable. Perform a stress test that changes parameters and tests the robustness of the model. For this step as a whole, many tools within the CAD program are useful.

P – Present the CAD work. This is typically the secondary outputs such as production drawings, renderings, animations, etc.

Designers should expect to use these steps iteratively. If the analysis shows that the model is not good, for example, returning to the model step is necessary.

A Few Closing Thoughts

Like so many things in life, becoming skilled at CAD requires both smarts and practice. This article was designed to help with the smarts part of that. It articulated the primary and secondary outputs of CAD. It did this so that we could better see the central role that CAD plays in the development process. The article listed 5 characteristics of good solid CAD models; these were provided so that when you practice you have a target to shoot for. The power of parametrics was also emphasized to illustrate that the parametrics facilitate design iteration — something that is fundamental to all design. CAD strategy was introduced as a way to work through what you’re going to do before you start the digital work. I cannot overemphasize how useful a written CAD strategy is to the process of CAD modeling. Finally, I shared my CAD process in hopes that it will help you get started or hone your own process.

References

[1] D. Lieu and S. Sorby, Visualization, Modeling, and Graphics for Engineering Design, 2017, Cengage Learning, Boston.

[2] Wikipedia, “Computer Aided Design,” https://en.wikipedia.org/wiki/Computer-aided_design, Accessed 15 July 2020.

[3] C. Mattson, “Mechanical Design,” BYU Design Review, 2020, https://www.designreview.byu.edu/collections/mechanical-design, Accessed 15 July 2020.

[4] J. Herron, “3D Model-based Design: Setting the Definitions Straight”, MCADcafe, 2010, https://www10.mcadcafe.com/nbc/articles/view_article.php?articleid=867959, Accessed 15 July 2020.

[5] J. Camba, M. Contero, P. Company, “Parametric CAD Modeling: An Analysis of Strategies for Design Reusability,” Computer-Aided Design, Volume 74, pages 18-31, 2016.

To cite this article:

Mattson, Chris. “Computer-Aided Design.” The BYU Design Review, 16 Jul. 2020, https://www.designreview.byu.edu/collections/computer-aided-design.