The Covid-19 Utah Mask: An interview with Michael Horito

As Co-Vid 19 evolved from an epidemic to a pandemic, there was a global shortage of Personal Protective Equipment (PPE). Desperate to help, makers began printing reusable masks in the hope to aid those on the front-lines; doctors, nurses, police and store personnel. Local government and various health groups put out calls for makers - anyone with a 3D printer - to print as many as they could to help with the shortage. Rocketship, a product design firm based in Provo, UT, was one of the many that answered the call. They designed what has become known as the "Utah mask". Michael Horito, from Rocketship, talked to us about their efforts.

BDR: Tell us a little about how you got involved:

Just as many other Makers in the area, and across the nation, we heard that there was a need for PPE. I think I saw a posting that the Provo Police were requesting anyone locally with a 3D printer to donate time and materials toward helping out. They also posted a simple open-source design that could be used. We've got 5 machines here that we use for the various projects we work on. So how could we refuse - it is a civic duty, right?

BDR: So you just started printing as many as you could?

Sort of. I think we printed 2 or 3 and then ran into a problem: we were out of filament and all of our sources were backlogged on orders by about 2 weeks due to the high demand. But we found a few other sources online and were able to arrange for delivery by the following week.

BDR: Then you started printing a bunch?

Yep. The need was high and everyone was in a rush. But while we had been waiting for the filament to arrive, we noticed that there seemed to be some deficiencies in the design. It didn't fit anyone here in our office. We were wondering how well it fits others. We started looking online and found a handful of other free designs. But they all had similar design problems.

BDR: Why weren't they fitting?

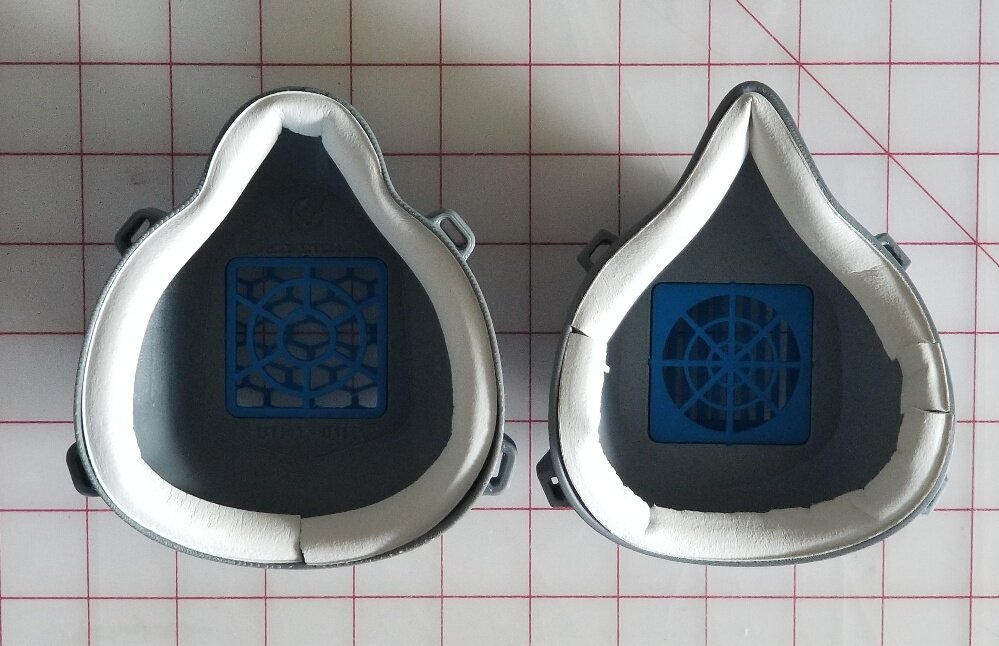

With a little analysis, we figured out what must have happened. Most designs seemed to be based on the forms you find with a typical respirator - the kind you might use when you are using a paint sprayer on your house. However, those respirators are made of silicone and other elastomers. In other words, they are flexible and designed to conform to a wide variety of face shapes. But almost everyone with a 3D printer is using rigid materials that won't conform. Then they are adding an off the shelf weatherstrip to help seal. But that was making the mask even smaller and less likely to fit the average person. Our guess is that the full assembly probably fits the 30th percentile and lower range of face sizes. That is a small part of the population. We wanted something that would fit a wider range - something like the 40th to 60th percentiles. That would cover about 70% -80% of the population.

The New Mask that Fits Most vs. the Original

BDR: Tell us a little about the changes you made:

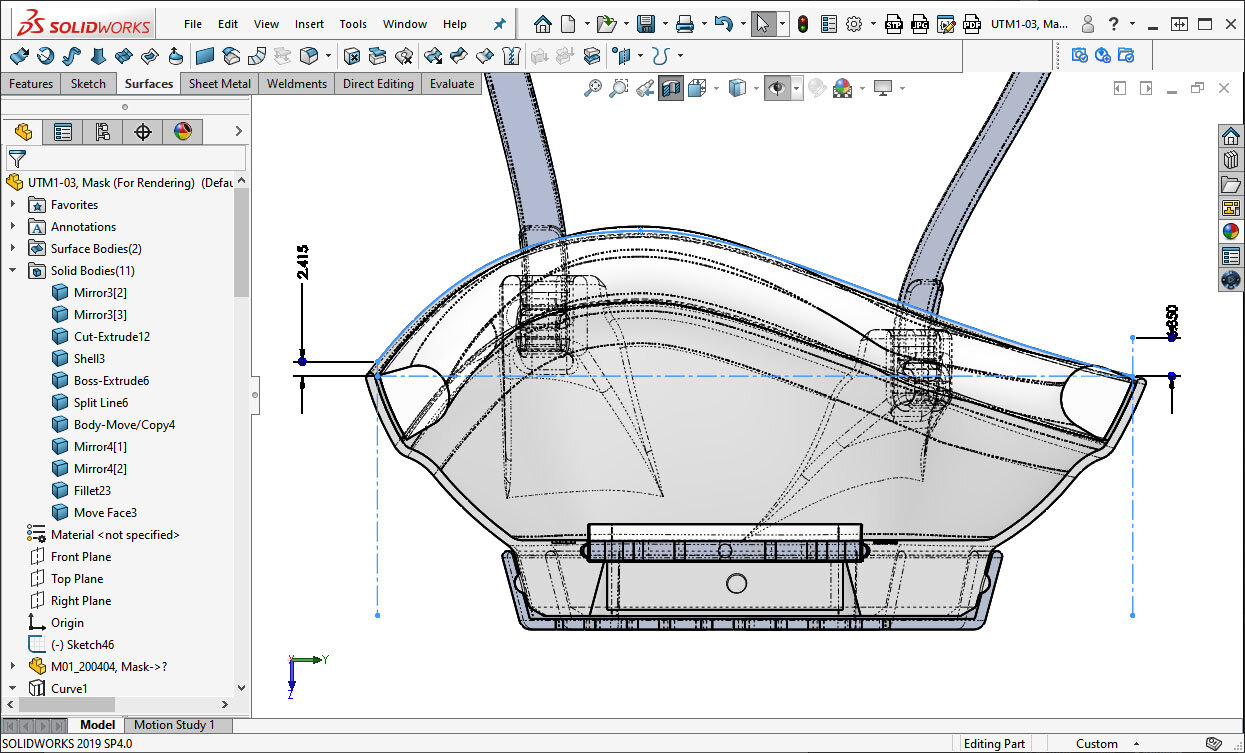

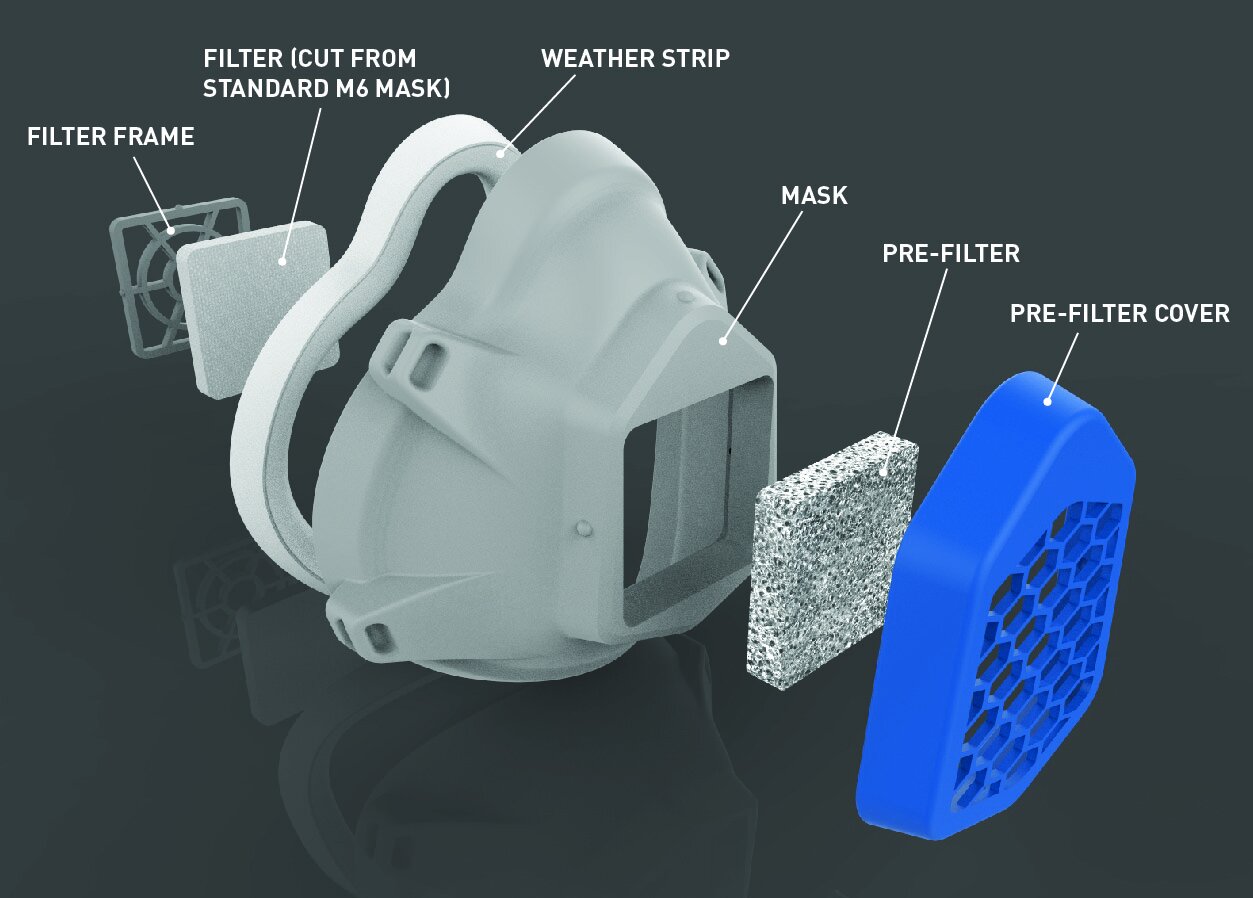

Well, it was a team effort. Everyone offered some of their thoughts as to how it could be improved. We sketched up a few ideas and evaluated them, changing and modifying as we went. I think we printed about 5 or 6 versions, with each one getting a little better. We tried to keep the general filter area about the same as others to optimize the use of N95 filter materials. But we created a recessed area that would accommodate the weatherstrip seal without making the mask smaller. Dropped the bridge down so that it could accommodate the wearing of eyeglasses or goggles.

Ready to be Printed

BDR: So now you have a mask that fits better?:

Yes, we think so. During this process, we also reached out to the Provo police and fire departments to see how their masks were fitting. As suspected, they were not fitting everyone very well. So we gave them a sample and they loved it. We got some good feedback from them on the fit. But there was more that had to be addressed - once you get going you start to see how much more could be done. Design is like that.

The New and Improved Mask

BDR: What other things did you address in the design?

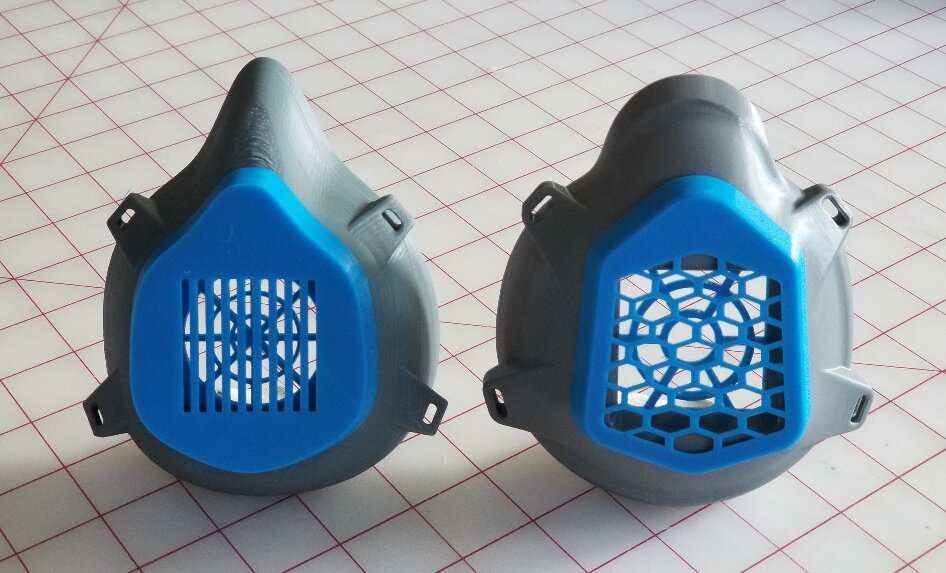

Well, once of the first things we noticed is that when we assembled one, the airflow was so low that it felt like you couldn't get enough air. In an emergency situation, the airflow situation would worsen. So we redesigned the filter holder so that we maximized the open spacing while still effectively holding the filter material. It makes me smile when I see them because the design was inspired by the front viewports of the Tie fighters from Star Wars :-)

TIE fighter Inspired Filter Holder

We also noticed that it was really annoying trying to get the elastic bands to fit correctly. The method was to tie the elastics to loophole features printed on the sides of the mask. But tying knots in elastic bands, then untying, loosening, and tying again was tedious at best. And some people wear them around their ears while others prefer to go around the head. The solution was pretty simple: we replaced the loop features with ladder-locks. These allow the straps to be pulled to tighten - the same way you adjust the straps on your backpack. Very easy and intuitive. And we left some space open to allow them to be tied just like the original design - because you never know what strap material people might be using. Just trying to consider all scenarios.

Original vs. Ladder-Lock Design

BDR: You make it sound easy:

It wasn't that hard. This is what we do. I think one of the biggest challenges was the DFM - Design for Manufacture. With everything you design you need to consider the process that will be used to manufacture the parts. And then you need to make sure that the design lends itself to that process. In this case, it is an FDM method of 3D printing. So we had to be careful with surfaces that made an angle with the ground plane less than 45 degrees. That forces some aspects of the design to be a little different than what might have been preferred. You just have to work through them so that the manufacturing process isn't preventing us from creating a good design.

We also wanted to accommodate smaller and larger faces at the ends of the size spectrum. So we created 2 more sizes. But these were not created by just scaling the whole mask. Human faces are not just scaled versions of each other. So we had to pull up some anthropometrics to make sure we increased parts of the mask in the same way that a human face might change in size - the difference between the 5th percentile and the 95th percentile is not the same for different parts of the face.

BDR: Sounds like this was a rewarding experience. Can you provide us with any takeaways?

Sure. First, I’d like to share my admiration and appreciation for the maker community. They are such a fun group of people. If not for them, we likely never would have thought to get involved.

So often designers tend to be reserved about sharing their raw ideas. I think it is often due to fear of failure or rejection. We want it to be perfect before we show it to others. Other times it may be because they are worried that others will take their idea and run with it. But the reality is that they could never follow through on all of the ideas that pop into their heads - there are just too many and not enough time.

But that willingness to share, the courage to put your talents out there is inspiring. It seems to be a common trait among makers and something we can all learn from.

Sometimes good ideas just seem to come out of nowhere. But more often they are the results of collaboration between people with diverse backgrounds.

When a group of people, designers, or anyone, sit together and start to talk about things a sort of magic starts to happen. Ideas are shared, the conversation becomes more interesting and new insights are created. The more the sharing, the deeper and more developed the insights. Brainstorming is really just sharing ideas so that others can build on it with you.

If you feel you are stuck in a rut, and can’t get your idea up and running, try sharing it with others. In the studio, I constantly share raw ideas with the staff. And I am always so impressed - and gratified - with how they can take a few words said, or a few lines drawing on paper and turn them into something amazing. Often something completely different than what I was originally thinking - but usually better. I find that satisfying :-)

The Utah Mask files can be downloaded here.

To cite this article:

Figueroa, Danni. “The Covid-19 Utah Mask: An interview with Michael Horito.” The BYU Design Review, 3 Jun. 2020, https://www.designreview.byu.edu/collections/utah-mask.